SHELL IS BUILDING AN ETHANE CRACKER PLANT NORTH OF PITTSBURGH. WHAT IS IT AND WHY IS IT COMING?

Shell is building an ethane cracker plant north of Pittsburgh. What exactly is a “cracker plant”? And why is it coming?

The simplest way to understand what an ethane cracker plant is, is to break down the terms. “Cracker” is an industry term that’s used to describe a plant that breaks up oil and gas molecules.

Ethane is one of several by-products produced when natural gas is extracted from the ground. When ethane is processed through a cracker facility, the result is ethylene. Ethylene is used to manufacture plastic and is used in 90 percent of manufactured products.

So the facility essentially converts a by-product from natural gas extraction into a product that is used in plastics manufacturing. The diagram from Royal Dutch Shell’s website lays out the process.

Why is one coming to Pittsburgh?

The vast majority of these facilities are densely located in the Gulf Coast Area, so building one in Beaver County is a somewhat unusual decision, but one that makes sense for several reasons.

1. Raw materials

One of the main reasons is that the Marcellus and Utica Shale Plays are located in the area and there is plenty of production to supply the plant.

As oil and gas production ramped up in Southwestern Pennsylvania, West Virginia and Ohio, there was a surplus of ethane. It didn’t make economic sense to transport the ethane to the Gulf Coast where existing cracker facilities were already located, so the solution was to burn-off the ethane. If you’ve ever been in an area with existing natural gas wells, you may have seen flames burning up from the well. It’s a little disconcerting when you first see it, but the process is burning off excess material that won’t be used.

While the recent drop in oil prices has hurt many producers, and lead to the loss of many oil and gas jobs, particularly in certain Pittsburgh submarkets, the production of natural gas from shale has resulted in an abundance of “cheap feedstock”. Essentially the abundance of ethane from natural gas production has outpaced its demand. These economic conditions result in workable profit margins to make the significant investment in an ethane cracker plant, even as energy producers suffer from poor margins with the exploration and production side of oil and gas.

2. Location Advantage

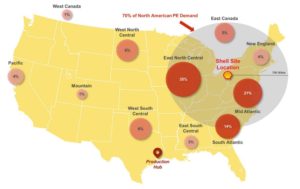

The plant’s Beaver County location is much closer to processors in the Midwest, Eastern U.S. and Canada, resulting in reduced transportation costs. Pittsburgh is located within 700 miles of 70% of North America’s Polyethylene demand as demonstrated on Shell’s map.

3. Labor Advantage

The Pittsburgh market contains less competition for skilled laborers than Shell would face in the Gulf Coast Market where the other cracker plants are located.

We’ll continue to look at the impact of the Ethane Cracker Plant and what it means to Pittsburgh in future articles.

Chris Harkins is a Senior Commercial Real Estate Energy Sector expert based in Pittsburgh, PA.

Sources:

http://www.npr.org/2012/01/12/145032971/projects-promise-of-jobs-has-appalachia-seeing-stars

http://www.bizjournals.com/pittsburgh/print-edition/2016/06/10/how-beaver-county-landed-the-cracker.html

http://www.hydrocarbonprocessing.com/Article/3440533/US-petrochemical-construction-boom-and-refining-margins-cushion-profits.html

http://www.plasticsnews.com/article/20160607/NEWS/160609845/shell-moving-forward-with-pennsylvania-petrochemical-complex